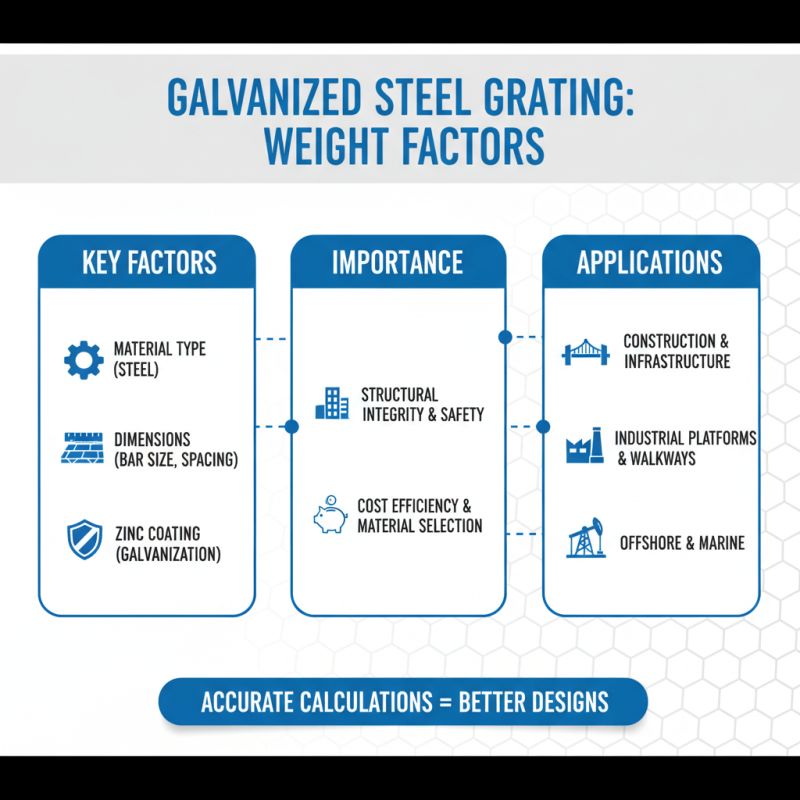

Galvanized Steel Grating Weight is a critical consideration in various industries where structural integrity and load-bearing capabilities are paramount. Understanding the weight factors and calculation methods associated with galvanized steel grating is essential for engineers, architects, and construction professionals. The weight of the grating can significantly influence the overall design of projects, affecting not only material selection but also transportation and installation processes.

In this discussion, we will delve into the key factors that contribute to the weight of galvanized steel grating, including the material thickness, spacing between bars, and the overall dimensions. Additionally, we will explore various calculation methods that help determine the accurate weight of grating, ensuring that professionals can make informed decisions based on precise data. By comprehensively understanding these elements, industry stakeholders can optimize their designs for efficiency and performance, ultimately leading to safer and more sustainable structures.

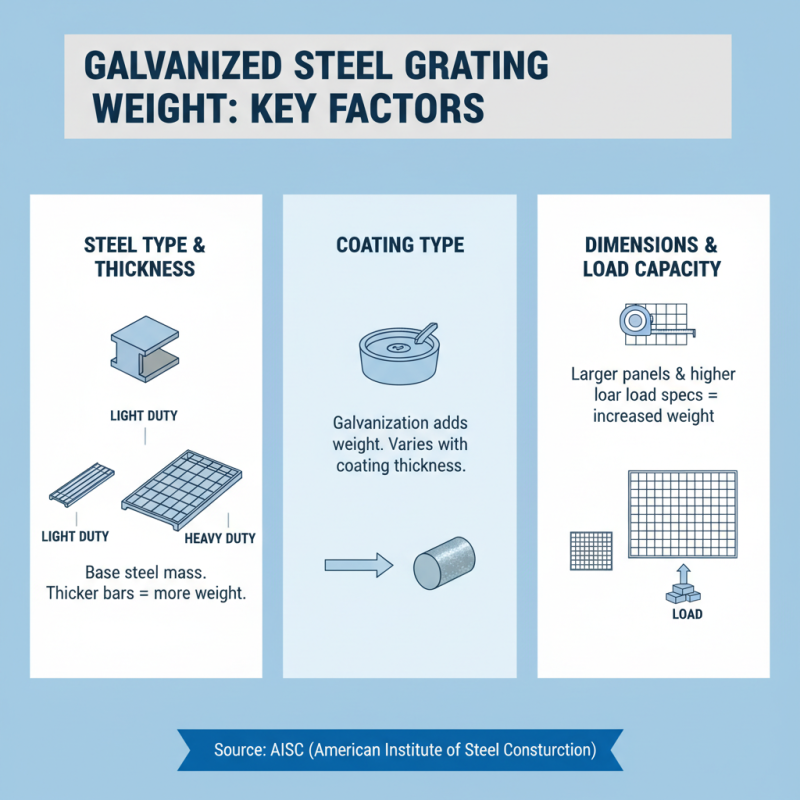

When considering the weight of galvanized steel grating, several critical factors come into play that directly impact its overall mass. The primary element influencing weight is the type of steel used in the grating, typically determined by its thickness and the type of coating applied. According to the American Institute of Steel Construction (AISC), the weight of steel grating can vary significantly based on its load-bearing capacity and dimensions. For example, heavier, thicker grating not only provides more strength but also increases the overall weight, potentially impacting installation and transportation.

Another significant factor is the design pattern of the grating itself. Various designs, such as those with larger openings or intricate patterns, can reduce material usage and thus weight. Recent industry reports, such as the global steel grating market analysis by Research and Markets, indicate that grating manufactured with optimized designs can save up to 20% of material compared to standard configurations without compromising on strength. Furthermore, the galvanization process adds a thin layer of zinc over the steel, which, while adding some weight, primarily serves to enhance corrosion resistance, ensuring longevity in demanding environments.

Environmental conditions can also play a role; grating used in corrosive settings may require thicker galvanization, further influencing weight. Consequently, it’s essential for designers and engineers to carefully calculate these factors and select the appropriate materials based on specific project requirements, balancing weight and performance to achieve optimal results.

When discussing galvanized steel grating, understanding the key materials and coatings is essential for determining its overall performance and durability. Galvanized steel grating typically consists of a base metal, such as carbon steel, which is then coated with a layer of zinc. This zinc coating acts as a protective barrier against corrosion, significantly extending the lifespan of the grating in harsh environments. The quality of the steel and the thickness of the zinc coating can impact both the weight and the functional characteristics of the grating.

The coating process, most commonly achieved through hot-dip galvanization, involves immersing the steel in molten zinc. This method ensures a robust bond between the zinc and steel, providing superior corrosion resistance compared to other methods like electroplating. Additionally, factors such as the type of zinc used, surface preparation, and the specific environmental conditions where the grating will be utilized all contribute to the coating's effectiveness.

Understanding these aspects is crucial for applications where longevity and safety are paramount, as the right combination of materials and coatings can make a significant difference in performance and weight considerations.

When it comes to calculating the weight of galvanized steel grating, precise measurements of dimensions and tolerances are critical. The standard dimensions typically used in the industry include thickness, width, height, and spacing between bars. According to industry reports, a common type of galvanized steel grating has a thickness ranging from 1/4 inch to 1 inch, while the spacing between bars can vary from 1 inch to 3 inches. Each of these parameters directly contributes to the overall weight, which is essential for ensuring structural integrity and compliance with safety regulations.

Accurate weight calculations also depend on adherence to the specified tolerances. The American National Standards Institute (ANSI) outlines that tolerances for steel grating should typically be within ±1/8 inch for critical dimensions. Reports show that even slight variations can lead to significant discrepancies in weight estimations, potentially affecting the load-bearing capacity of the grating. For instance, a detailed analysis demonstrated that a change in thickness of just 1/8 inch in a 3-foot by 10-foot grating can vary the weight by approximately 15 pounds. Thus, meticulous measurement practices are paramount to ensure that the final product meets both regulatory standards and project specifications.

When calculating the weight of galvanized steel grating, several factors must be considered to ensure accuracy. The primary elements include the dimensions of the grating, including its length, width, and thickness, as well as the type of material used in its construction.

The weight is typically determined using the formula:

Weight = Volume x Density. This means one needs to calculate the volume of the grating by multiplying its surface area by the thickness, and then multiplying this volume by the density of galvanized steel, which is approximately 490 pounds per cubic foot.

Additionally, understanding the design of the grating—such as the spacing between the bars and the overall pattern—can also affect the weight calculation. For instance, the presence of load-bearing bars and their orientation can influence not just the structural integrity but also the weight distribution.

To achieve the most precise calculation, users should have access to detailed specifications for the type of galvanized steel grating in question, and it may also be beneficial to consult construction guidelines that provide standardized measurements for different designs.

Understanding the weight factors of galvanized steel grating is essential for various practical applications across multiple industries. Accurate weight calculations help engineers and designers select the right materials for their projects, ensuring structural integrity and safety. In construction and infrastructure development, for instance, understanding how weight can influence load-bearing capabilities leads to better design choices, potentially reducing costs and material wastage.

Additionally, in the context of transportation and logistics, knowing the weight of galvanized steel grating is vital for planning. From calculating the allowable load on vehicles to ensuring compliance with shipping regulations, accurate weight metrics play a crucial role. Implications of these calculations extend to project timelines and budgeting, as weight impacts not only material costs but also handling and installation processes. Ultimately, a thorough grasp of weight-related factors aids in making informed decisions that optimize both functionality and efficiency in various applications.