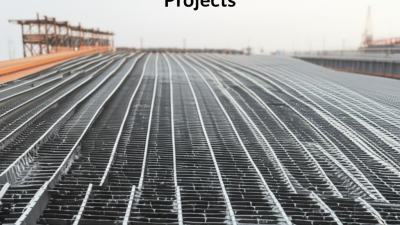

In the construction and industrial sectors, choosing the right materials is crucial for ensuring safety and efficiency. One such material that has gained prominence is Composite Steel Grating, known for its strength, durability, and lightweight properties. According to a report by the Global Market Insights, the composite grating market is projected to exceed USD 1.5 billion by 2026, highlighting the increasing demand across various applications, including walkways, platforms, and drainage systems. However, with a myriad of options available, selecting the best composite steel grating can be a daunting task for project managers and engineers. This blog aims to provide essential tips for identifying quality manufacturers, ensuring that your project benefits from high-performance materials that meet industry standards while aligning with your specific needs.

When selecting composite steel grating for your projects, several key factors should guide your decision-making process. First and foremost, consider the load-bearing capacity required for your application. Depending on the environment, the grating must withstand not only the weight but also potential impacts. Ensure that the specifications match your project's needs to avoid frequent replacements or maintenance issues.

Another essential tip is to evaluate the environmental conditions that the grating will be exposed to. Composite steel grating comes in various materials, each offering different resistance to corrosion, chemicals, and UV light. For instance, if your project is in a harsh or outdoor setting, opt for grating that is specifically designed to endure these challenges, thus extending its life span and reliability.

Lastly, factor in the installation process and maintenance requirements. Choosing grating that is easy to install can save time and reduce labor costs. Furthermore, look for grating that requires minimal upkeep to ensure a low total cost of ownership. Taking these aspects into account will help you select the ideal composite steel grating for your needs.

When selecting composite steel grating for your projects, understanding industry standards is crucial.

These standards not only ensure safety and durability but also help you choose the right product for specific applications. The American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM) set forth various guidelines that govern the design, manufacturing, and performance of composite steel grating.

Familiarizing yourself with these standards will provide a strong foundation for making informed decisions and ensure compliance with local regulations.

Moreover, different industries may have specific requirements that affect the type of composite steel grating you choose. For example, environments exposed to corrosive substances might necessitate grating with enhanced corrosion resistance, while heavy-duty industrial applications may need grating that adheres to stringent load-bearing standards.

By aligning your project needs with relevant industry standards, you can enhance safety, efficiency, and longevity in your applications, ultimately ensuring that your composite steel grating solution performs optimally over time.

When embarking on projects that utilize composite steel grating, it's essential to acknowledge the common challenges that arise during installation. A prominent issue is ensuring proper alignment and leveling. According to a recent report by the Steel Grating Manufacturers Association, nearly 30% of installation failures can be attributed to improper alignment. This can lead to uneven load distribution, affecting durability and safety. To mitigate this challenge, it's crucial to conduct a pre-installation assessment of the site to establish clear alignment guidelines.

Another challenge is managing the weight and handling of composite steel grating panels, which can be cumbersome. A study by the International Institute of Steel Applications indicated that improper handling practices contribute to a 25% increase in installation time. Incorporating basic rigging practices and utilizing appropriate lifting equipment can significantly ease the process. One tip is to engage a team trained in material handling to streamline the workflow and promote safety.

As installation techniques evolve, staying informed about the latest materials and methods is essential. The Composite Institute emphasizes the importance of selecting grating with adequate load capacity to meet project specifications, as failing to do so can lead to additional complications down the line. Always consult the manufacturer's guidelines and consider factors like environmental exposure, which can impact grating performance in specific settings.

When selecting composite steel grating for your projects, understanding the different types and their respective advantages and disadvantages is crucial.

Composite steel grating comes in various forms, including molded and pultruded options.

Molded grating, often made from a combination of fiberglass and steel, offers excellent anti-slip properties and resistance to corrosion, which makes it ideal for wet or chemical-laden environments.

A report by the Composite Engineering Institute indicated that molded grating can reduce maintenance costs by up to 30% in corrosive settings.

On the other hand, pultruded grating offers higher strength-to-weight ratios and is typically easier to install due to its lighter weight.

However, it may not have the same level of anti-slip characteristics as molded options.

According to a study conducted by the American Composites Manufacturers Association, pultruded grating is gaining popularity in industrial applications where load-bearing capabilities are essential but where slip hazards are minimal.

Tip: Always consider the specific environmental conditions and load requirements of your project when choosing between grating types.

Additionally, surface treatments can enhance the performance of either grating type, so evaluating these options can lead to significant long-term benefits in safety and durability.

When it comes to composite steel grating installations, proper maintenance plays a crucial role in ensuring their longevity. According to the National Association of Steel Distributors, regular inspection and maintenance can extend the lifespan of steel grating systems by up to 30%. This highlights the importance of incorporating routine checks and proper care into your project planning.

One essential tip for maintaining composite steel grating is to conduct regular inspections for signs of wear and tear, particularly in high-traffic areas. Look for any cracks, rust, or loose connections. This proactive approach can prevent small issues from escalating into costly repairs. Additionally, keeping the surface clean can help prevent environmental contaminants from degrading the material over time.

Another effective maintenance tip is to consider protective coatings. Applying a non-slip coating not only enhances safety but also provides an extra layer of protection against corrosion. According to industry research, the use of such coatings can reduce maintenance costs by up to 40%, making it a wise investment for long-term durability. Implementing these strategies will ensure your composite steel grating continues to perform effectively for years to come.