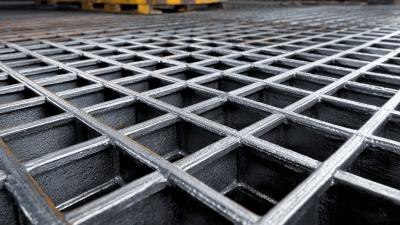

Press Welded Steel Grating has become an integral component in various industrial applications due to its exceptional durability and load-bearing capacity. According to a report by the

American National Standards Institute (ANSI), industrial flooring systems must withstand significant weights, often exceeding

1,500 pounds per square foot in heavy industrial environments.

Press Welded Steel Grating, known for its robust construction and resistance to wear and corrosion, meets these demanding requirements effectively. Additionally, a study published in the

International Journal of Steel Structures highlighted that Press Welded Steel Grating can endure heavy dynamic loads and provide superior performance in high-traffic areas.

With its ability to maintain structural integrity under intense conditions, this type of grating is increasingly favored in industries such as

manufacturing, construction, and petrochemicals, ensuring safety and efficiency in diverse operational settings.

Press Welded Steel Grating, known for its robust construction and resistance to wear and corrosion, meets these demanding requirements effectively. Additionally, a study published in the

International Journal of Steel Structures highlighted that Press Welded Steel Grating can endure heavy dynamic loads and provide superior performance in high-traffic areas.

With its ability to maintain structural integrity under intense conditions, this type of grating is increasingly favored in industries such as

manufacturing, construction, and petrochemicals, ensuring safety and efficiency in diverse operational settings.

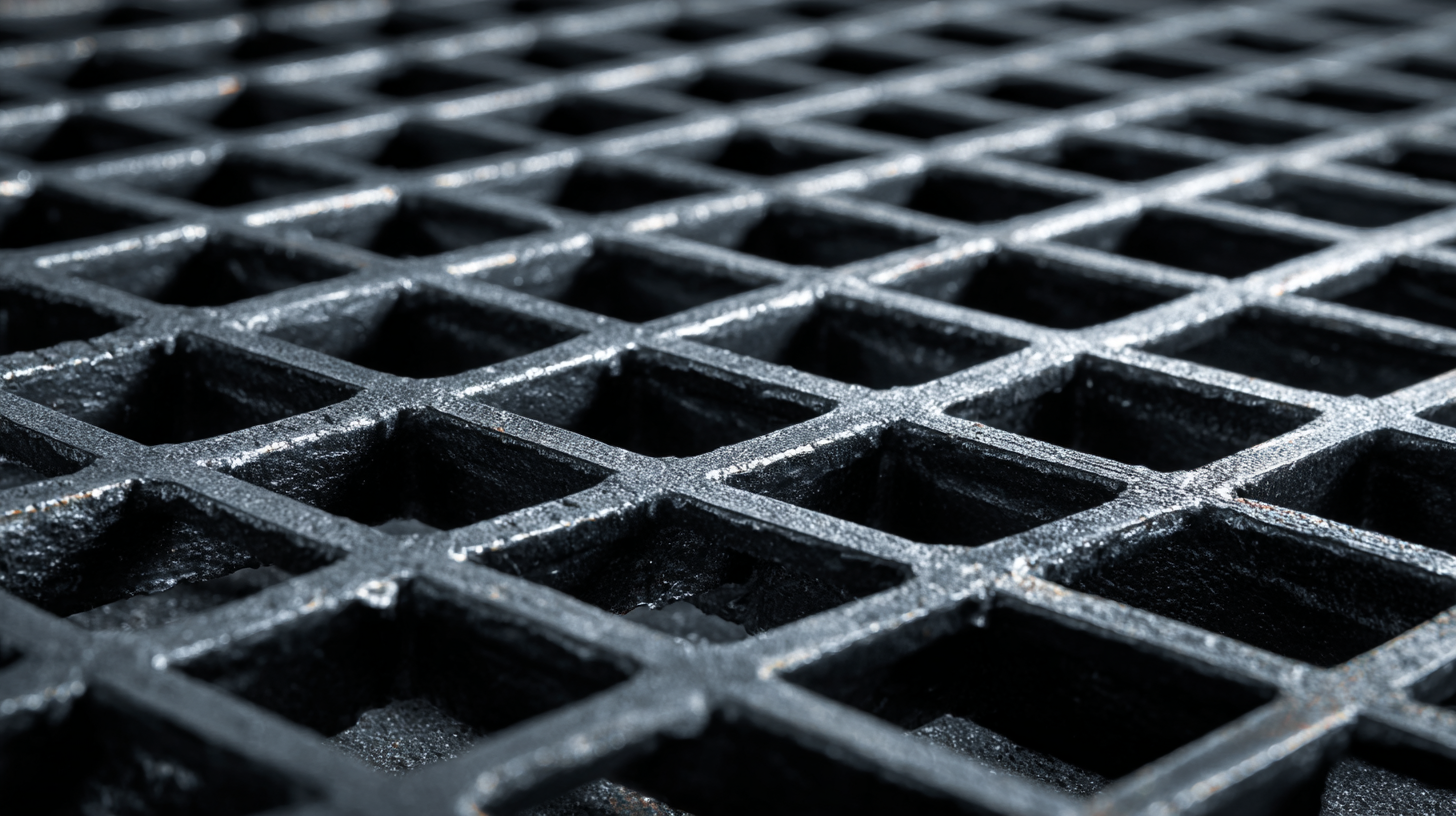

Press welded steel grating is widely used in various industrial applications due to its strength and versatility. However, its durability can be significantly influenced by several factors, especially in harsh environments. One of the primary concerns is corrosion, which can occur when the steel is exposed to moisture, chemicals, or extreme temperatures. Proper surface treatments, such as galvanization or powder coating, are essential to enhance resistance against these environmental factors and extend the lifespan of the grating.

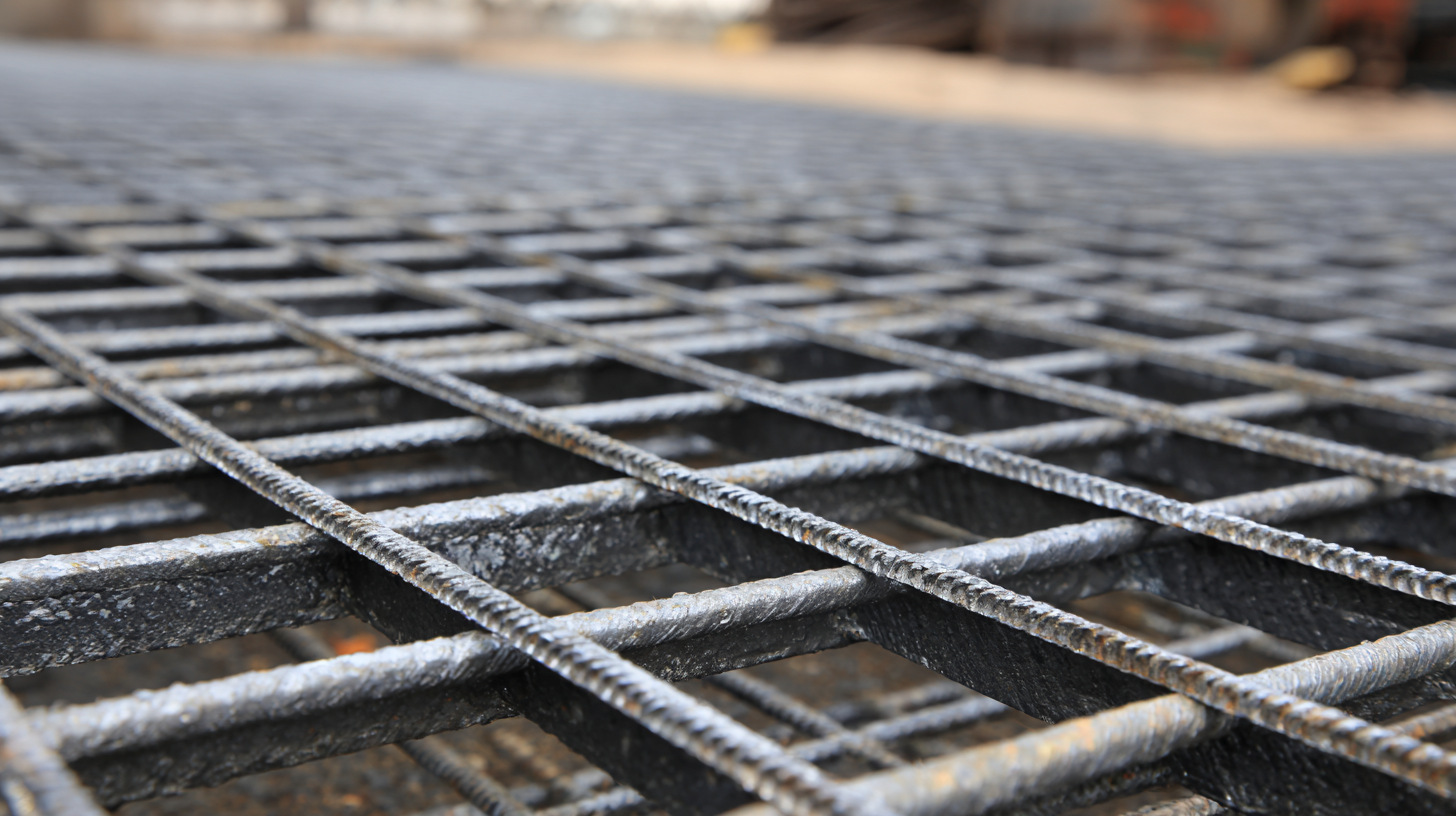

Another critical aspect affecting the durability of press welded steel grating is the load capacity it must support. In industrial settings, the grating often bears heavy loads, which can lead to deformation or failure if the design and welding process are not properly executed. Additionally, the choice of materials and the quality of the welding play vital roles in maintaining structural integrity. Regular maintenance and inspections are necessary to identify any signs of wear or damage that may compromise the safety and reliability of the grating in demanding applications.

When assessing the load capacity of press welded steel grating, several key considerations must be taken into account to ensure optimal performance in industrial applications. Firstly, the material's tensile and yield strength plays a crucial role in determining how much load the grating can safely support. High-quality steel with superior mechanical properties is essential to withstand heavy loads and resist deformation over time. Additionally, the design of the grating, including the spacing and thickness of the bars, greatly influences its overall load-bearing capacity. Wider spacing may reduce weight, but it can also compromise strength and durability.

Another vital aspect to consider is the environment in which the steel grating will be used. Factors such as exposure to corrosive substances, temperature fluctuations, and potential impacts from machinery must be evaluated. Specialized finishes or coatings can enhance resistance to these environmental challenges, prolonging the lifespan of the grating. Regular inspection and maintenance protocols are also important to identify any signs of wear or damage, ensuring that the press welded steel grating continues to perform effectively under load throughout its intended lifespan.

| Material Type | Load Capacity (kN/m²) | Thickness (mm) | Applications | Durability Rating (Years) |

|---|---|---|---|---|

| Steel Grating A | 10.5 | 30 | Walkways, Platforms | 15 |

| Steel Grating B | 12.0 | 40 | Heavy Load Areas | 20 |

| Steel Grating C | 9.0 | 25 | Drain Covers, Grates | 10 |

| Steel Grating D | 14.5 | 50 | Bridges, Highways | 25 |

In industrial settings, steel grating plays a critical role in safety and operational efficiency. Despite its robust design, several common failures can compromise its integrity. One prevalent issue is corrosion, which can lead to structural weakness and eventual failure. According to a report by the American Welding Society, over 30% of steel grating failures in corrosive environments are attributed to inadequate protective coatings. To mitigate this risk, applying high-quality galvanized or powder-coated finishes can enhance the longevity of press welded steel grating.

Another significant failure mode is fatigue cracking, which occurs when the grating is subjected to repeated loading cycles. The Metal Bar Grating Manufacturers Association states that these cracks often initiate at weld points or in areas of high stress concentration. Regular inspections and the implementation of load management strategies can prevent such failures. Additionally, engineering studies suggest incorporating load distribution features in the design can significantly enhance load capacity, thereby reducing the risks associated with fatigue. By addressing these common failures proactively, industrial facilities can improve safety and extend the lifespan of steel grating installations.

This bar chart illustrates the load capacity of various types of press welded steel grating used in industrial applications. Each type demonstrates differing load capacities, highlighting the importance of selecting the appropriate type for specific industrial needs. Type E has the highest load capacity, making it ideal for heavy-duty applications.

Effective maintenance and inspection of press welded steel grating are crucial for ensuring their longevity and optimal performance in various industrial applications. Regular inspections should be conducted to identify potential issues such as corrosion, cracks, or misalignments. By spotting these problems early, you can avoid costly repairs and ensure safety in the workplace. It's recommended to schedule inspections at least bi-annually, with a more frequent schedule in environments that are harsher or involve heavier loads.

Tips: Always clean the steel grating regularly to remove dirt, debris, and moisture that may promote corrosion. Consider using a mild detergent and a brush to avoid scratching the surface. Additionally, apply a protective coating every few years based on the specific environment to enhance the grating's lifespan.

Routine maintenance also involves checking the load capacity regularly. Ensure that the grating is suited for the specific loads expected in your application. Users should keep records of any modifications or repairs made to the grating to maintain an accurate history for safety assessments. Implementing these best practices effectively will help maintain the integrity and durability of press welded steel grating in your facility.

When selecting press welded steel grating for industrial applications, understanding the specifications is crucial for enhancing load performance. The choice of materials, bar dimensions, and spacing between the bearing bars directly influences the durability and load capacity of the grating.

Higher quality steel with better tensile strength can withstand greater loads, while wider bearing bars provide increased support, reducing the risk of deformation under heavy weights.

Furthermore, the load performance can be optimized by considering the environmental conditions where the grating will be installed. Factors such as exposure to corrosive chemicals, extreme temperatures, and heavy foot traffic can significantly affect the longevity and functionality of the grating. It’s essential to select grating that complies with relevant industrial standards, ensuring it meets the specific mechanical and environmental requirements of the application. By carefully evaluating specifications and their implications, businesses can make informed decisions that enhance both safety and efficiency in industrial settings.