In the realm of construction and design, selecting the right materials is crucial to the overall success of any project. One key element that often goes overlooked is the type of grating used, particularly the Black Plain Grating. Renowned industry expert, John Smith, emphasizes, "The choice of grating can significantly impact both the aesthetic and functional aspects of a project." This statement highlights the importance of making an informed decision when it comes to grating options.

When choosing Black Plain Grating, several factors must be considered, including load-bearing capacity, environmental conditions, and intended use. The versatility of Black Plain Grating allows it to fit various applications, from industrial settings to decorative landscaping, making it an appealing choice for many professionals. By understanding the specific requirements of your project, you can better navigate the various options available in the market, ensuring that you select the most appropriate grating solution for your needs.

In this guide, we will explore the essential criteria to help you make an informed decision regarding Black Plain Grating, setting a solid foundation for your project’s success.

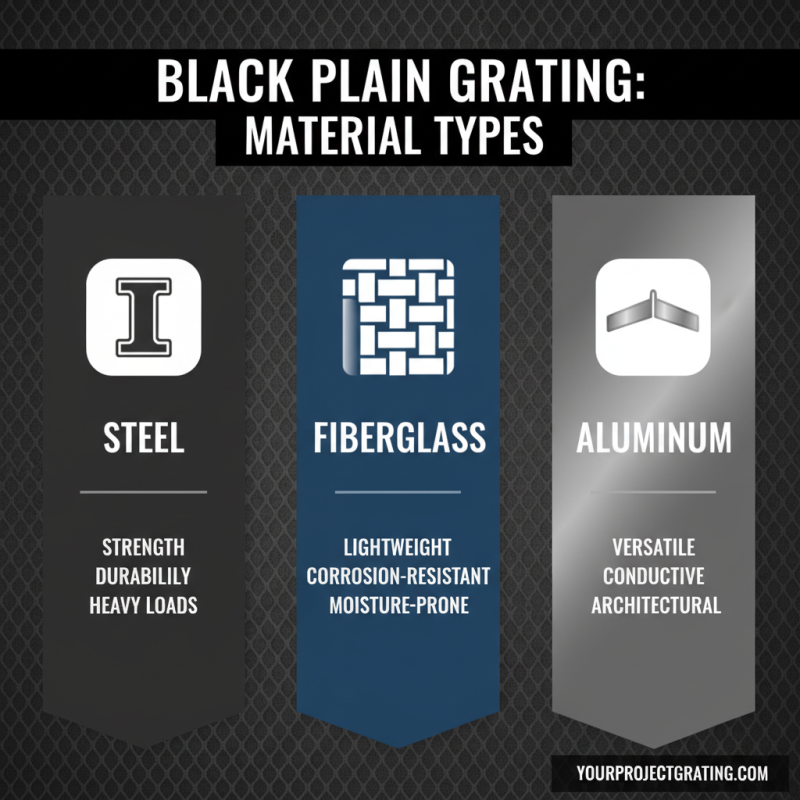

When selecting the right black plain grating for your project, it's crucial to understand the various types available in the market. Generally, black plain grating is classified into several categories based on materials, patterns, and applications. The most common materials include steel, fiberglass, and aluminum. Each material offers distinct advantages; for instance, steel grating is known for its strength and durability, making it ideal for heavy-load applications, while fiberglass grating is lightweight and resistant to corrosion, making it suitable for environments with moisture.

In addition to material differences, the design and pattern of grating play an essential role in your decision. Black plain grating can come in solid sheets or bar grating forms, each serving different purposes. Solid sheets provide a flat surface ideal for pedestrian walkways, offering a slip-resistant texture, while bar gratings allow for better drainage and airflow, making them more suitable for industrial applications. Understanding these distinctions helps ensure that the selected grating matches your specific requirements, balancing functionality with aesthetic appeal in your project.

When selecting black plain grating for your project, a critical factor to consider is its load-bearing capacity. This capacity is influenced by multiple parameters, including the material composition, the dimensions of the grating, and the spacing of the supports. Understanding these variables enables you to choose a grating that can safely support the anticipated loads without compromising structural integrity. It is essential to consult load charts or guidelines during this evaluation process to ensure compliance with safety standards and project requirements.

Furthermore, conducting a thorough assessment of the intended environment is vital. Factors such as environmental conditions, potential for dynamic loads, and durability against corrosion can significantly impact the performance of black plain grating. For instance, grating used in industrial settings might require a higher load-bearing capacity than those for residential applications. Consequently, by comprehensively analyzing both the load requirements and environmental factors, you can make an informed decision that ensures the grating's longevity and effectiveness within your specific project framework.

When selecting the right black plain grating for your project needs, understanding the key material properties that influence its durability is essential. One of the primary factors is the material composition. Gratings made from high-quality steel or fiberglass often exhibit superior strength and resistance to environmental stresses. Their ability to withstand heavy loads and resist corrosion significantly impacts their longevity, especially in harsh or variable conditions.

Another critical aspect is the surface finish of the grating. A textured or coated finish can enhance slip resistance, making it safer for foot traffic and reducing wear over time. Additionally, UV resistance in certain materials helps prevent degradation when exposed to sunlight, which is particularly important for outdoor applications. Evaluating these material properties ensures that the chosen black plain grating not only meets the immediate project requirements but also stands the test of time, providing a functional and safe solution for various applications.

| Property | Description | Impact on Durability |

|---|---|---|

| Material Type | Common materials include steel, fiberglass, and aluminum. | Different materials have varying resistance to corrosion, chemicals, and wear. |

| Load Capacity | The maximum load the grating can support without deformation. | Higher load capacities generally indicate enhanced structural integrity and longevity. |

| Thickness | The thickness of the grating material. | Thicker gratings are often more durable and able to withstand harsher conditions. |

| Surface Treatment | Coatings or treatments applied to enhance corrosion resistance. | Effective treatments improve lifespan by protecting against environmental factors. |

| Environmental Resistance | Ability to endure extreme temperatures, UV exposure, and moisture. | Higher resistance correlates with longer service life in adverse conditions. |

When choosing the right black plain grating for your project, evaluating the cost-effectiveness of various options is crucial. According to a recent industry report by the International Grating Association, the cost of materials can vary significantly based on the type, thickness, and manufacturing processes. Specifically, the report highlights that while plastic and fiberglass variants may have a lower initial purchase price, their lifespan and maintenance costs can lead to higher overall expenses compared to more durable materials like steel or aluminum.

Moreover, a comparative analysis of maintenance costs indicates that properly installed steel grating can last up to 30% longer than its counterparts when subjected to similar environmental conditions, ultimately resulting in lower life-cycle costs. A survey of industry professionals found that nearly 70% prioritize long-term cost efficiency over initial savings when selecting materials for their projects. To achieve the best balance between upfront costs and durability, it's essential to assess the specific environmental conditions your grating will face, such as exposure to chemicals or physical wear, and to align these factors with the best-suited grating option.

When selecting black plain grating for various projects, it is essential to comply with industry standards to ensure safety, durability, and performance. According to a report from the American National Standards Institute (ANSI), grating must meet certain specifications to maximize load-bearing capacity and minimize risk of failure. For instance, the selection of grating materials should align with ASTM specifications which address factors such as tensile strength and resistance to environmental impact, which are critical in industrial applications.

Additionally, understanding load classification is crucial for compliance. The Load and Resistance Factor Design (LRFD) methodology outlines the necessary load factors for different applications, highlighting the significance of choosing the right grating type for specific project requirements. An analysis by the National Association of Architectural Metal Manufacturers emphasizes that adhering to these guidelines can prevent structural inadequacies and enhance the longevity of the installation.

For projects involving pedestrian access, the selection criteria would incorporate slip-resistance safety standards to safeguard users, ensuring that the chosen grating not only meets aesthetic needs but also complies with the necessary safety regulations.

Overall, to ensure that the black plain grating chosen for your project meets industry standards effectively, it is advisable to conduct a thorough review of the applicable specifications and regulations. This approach not only aligns with best practices but guarantees that the final product can withstand the demands of its intended environment, ultimately supporting the integrity of the entire project.