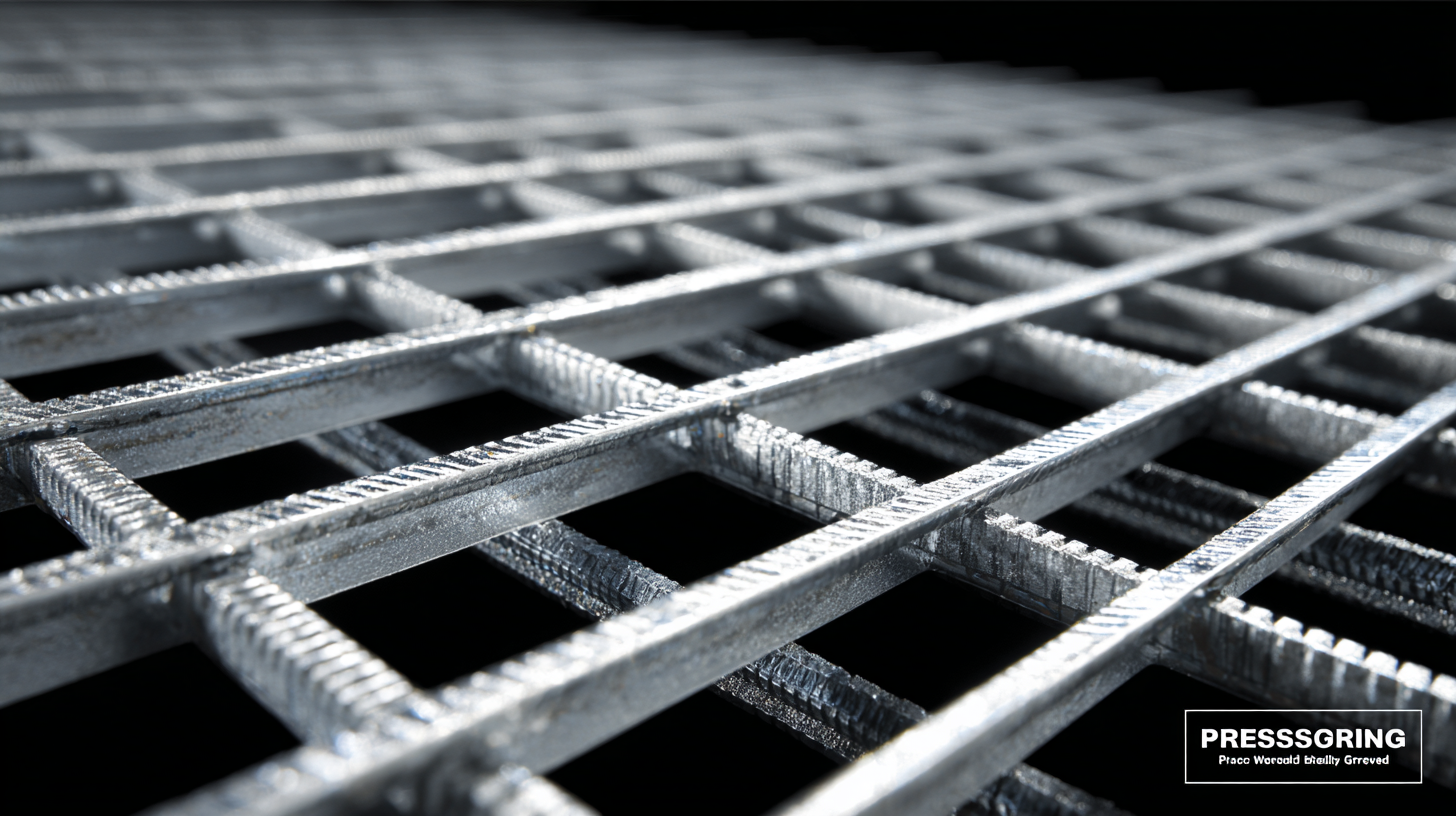

When embarking on a construction or renovation project, selecting the right materials is crucial for both functionality and aesthetics. One such material that has gained popularity in various applications is Press Welded Steel Grating. Known for its strength and durability, this type of grating offers an array of benefits, making it a favored choice for industrial flooring, walkways, and platform systems. However, with numerous options available in the market, choosing the best Press Welded Steel Grating for your specific needs can be a daunting task. This blog aims to provide top strategies that will guide you in making an informed decision, ensuring that the grating you choose not only meets your project's requirements but also enhances safety and efficiency. Join us as we explore the essential factors to consider when selecting Press Welded Steel Grating for a successful project outcome.

When selecting the best press welded steel grating for your project, it's crucial to understand the various types available and their unique characteristics. Press welded steel grating is commonly classified into several types, such as light duty, medium duty, and heavy duty. According to the American National Standards Institute (ANSI), a typical light-duty grating supports a load of up to 1,000 pounds per square foot (psf), while heavy-duty grating can handle loads over 1,200 psf. Selecting the right type tailored to specific load requirements ensures safety and longevity in applications.

Recent events in the shipbuilding industry underscore the importance of quality in welding practices related to steel structures. With the U.S. Navy investigating faulty welds on submarines and aircraft carriers, it is clear that improper welding can lead to significant safety issues and extended project timelines. Reports indicate that 26 ships were affected by these faulty welds, highlighting the imperative for stringent quality control measures in welding steel components. When choosing press welded steel grating, consider the manufacturing standards and quality assurances provided by suppliers to avoid similar pitfalls. Quality assurance, backed by standards compliance, can prevent costly failures and maintain structural integrity in your projects.

When selecting the best press welded steel grating for your project, several key factors must be considered to ensure optimal performance and longevity. First and foremost, understanding the load requirements is crucial. According to the American National Standards Institute (ANSI) and the Steel Grating Manufacturers Association (SGMA), different applications will demand varying load capacities. For instance, pedestrian walkways may require grating with a load rating of 1,200 pounds per square foot (psf), while heavy industrial settings could necessitate ratings of up to 5,000 psf. This variation emphasizes the importance of accurately assessing the anticipated load conditions before making a selection.

Another critical factor is the environmental conditions to which the steel grating will be exposed. In corrosive environments, such as those found in wastewater treatment facilities or coastal areas, choosing the right material finish is essential. A report by the National Association of Steel Fabricators indicates that 20-30% of steel degradation in these settings can be mitigated through proper surface treatment like galvanized or stainless steel options. This investment not only enhances durability but can also significantly reduce maintenance costs over the lifespan of the grating. Engaging with qualified manufacturers or suppliers can provide valuable insights into both load specifications and material suitability for specific environmental challenges.

When selecting the best press welded steel grating for your project, considering the manufacturer is crucial. Chinese manufacturers have established a strong reputation in the global market for providing high-quality steel grating products. One significant advantage is their ability to combine cost-effectiveness with robust production capabilities. With advancements in technology and increased efficiency, these manufacturers can offer competitive prices without compromising quality. This makes them an attractive option for projects that require both durability and affordability.

Moreover, the current discussion surrounding tariffs and import taxes has led to some complexities in sourcing materials. While many U.S. industries may have concerns about the implications of tariffs, steel and aluminum producers have expressed support for such measures. They believe that tariffs can level the playing field by reducing competition from cheaper imports. This perspective reinforces the value of partnering with Chinese manufacturers, as they often provide products that meet stringent international standards, allowing U.S. businesses to focus on quality while navigating the complexities of the current market landscape.

When selecting the best press welded steel grating for your project, evaluating quality and performance is crucial to ensure longevity and efficiency. Start by assessing the material specifications, particularly the type of steel used. High-quality steel should resist corrosion, especially in environments prone to moisture or chemicals. Additionally, consider the load-bearing capacity of the grating. It must support the expected weight while maintaining structural integrity, which can be determined by reviewing the manufacturer's load charts.

Another essential aspect to evaluate is the welding quality. The welds should be uniform and free from defects; this not only affects the overall strength but can also influence the durability of the steel grating. Additionally, look for any certifications that indicate compliance with industry standards. Performance can also hinge on the grating's surface finish; a non-slip coating can improve safety in high-traffic areas. Keep these factors in mind to ensure that your chosen steel grating will meet the specific demands of your project effectively.

The global steel grating market has witnessed significant transformation driven by innovation and sustainability. According to a report by Mordor Intelligence, the market is projected to grow at a compound annual growth rate (CAGR) of approximately 5% from 2021 to 2026. This growth is fueled by rising demands in various sectors, particularly in construction and infrastructure, where durable and versatile materials like press welded steel grating are essential. The adoption of advanced manufacturing technologies, such as automated welding and improved material processing, has enhanced the efficiency and strength of steel gratings, making them more appealing for large-scale projects.

Innovations in the steel grating industry are also focusing on sustainability. A report from Research and Markets indicates that the increasing emphasis on eco-friendly construction materials is driving manufacturers to explore recycled steel options. This shift not only reduces the carbon footprint but also meets the regulations set forth in numerous countries regarding sustainable building practices. Furthermore, innovative designs and coatings that improve longevity and resistance to corrosion and environmental factors are becoming more prevalent, ensuring that projects utilizing steel grating can withstand the test of time and demanding conditions. As these trends unfold, selecting the right press welded steel grating becomes vital for any project, highlighting the importance of keeping abreast of global innovations.

| Dimension | Material Type | Surface Treatment | Load Capacity (kN) | Application Area |

|---|---|---|---|---|

| 30mm x 40mm | Carbon Steel | Hot-Dip Galvanized | 15 | Walkways |

| 40mm x 60mm | Stainless Steel | Electrolytic Polishing | 25 | Industrial Flooring |

| 25mm x 30mm | Aluminum | Anodized | 10 | Drainage Covers |

| 50mm x 100mm | Mild Steel | Powder Coated | 30 | Heavy Machinery |