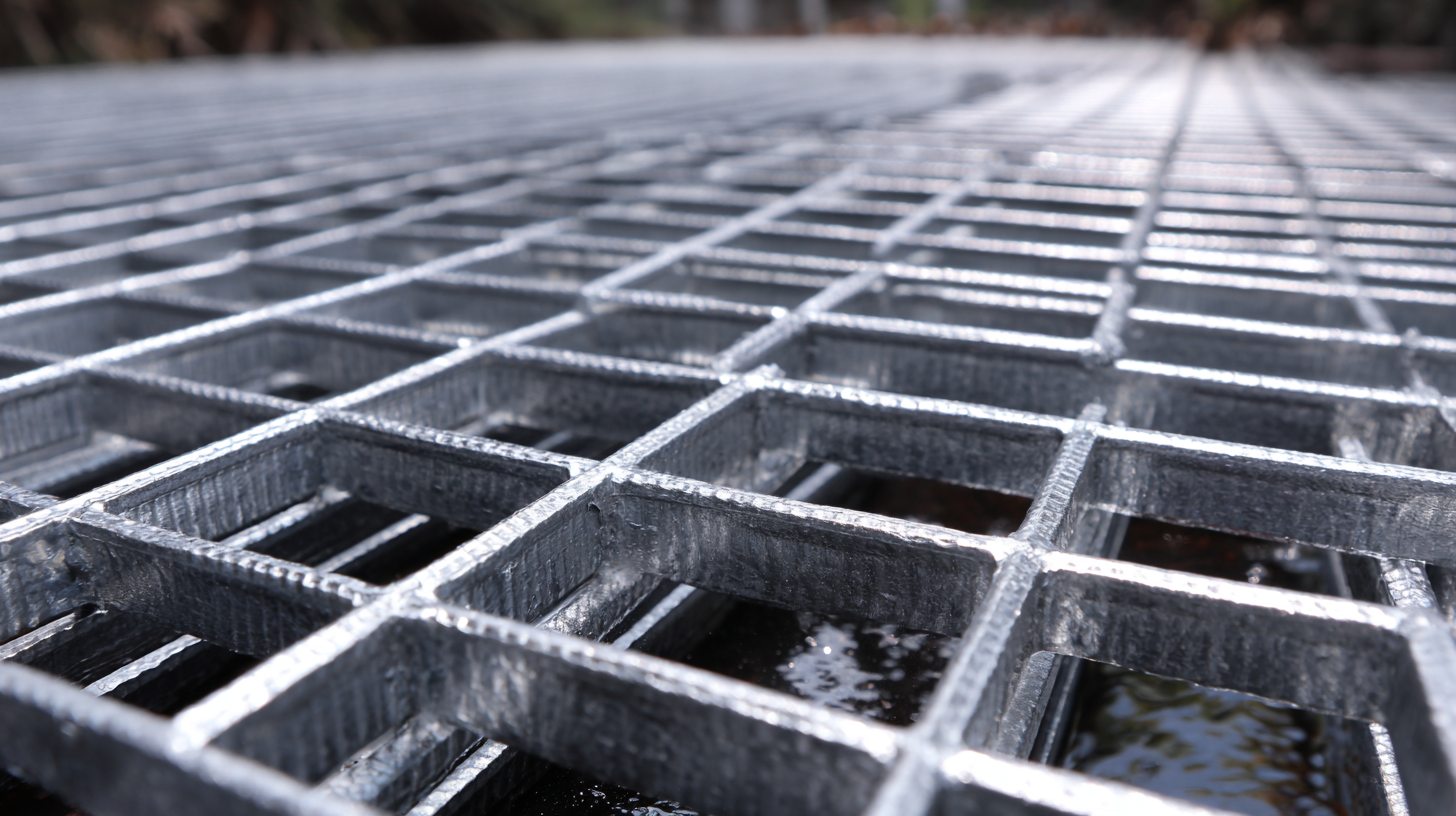

As industries evolve, the demand for versatile and durable construction materials continues to rise. One such material that has gained significant attention is Mill Finish Steel Grating, which is renowned for its strength, longevity, and versatility in various applications, ranging from manufacturing to infrastructure. According to recent market analyses, the global steel grating market is projected to reach approximately $1.3 billion by 2025, driven by increasing infrastructure projects and a growing emphasis on industrial safety. This trend underscores the necessity for businesses to select the best Mill Finish Steel Grating that aligns with their specific operational needs. Factors such as load capacity, environmental resistance, and maintenance requirements play a critical role in this decision-making process, making it essential for industry professionals to stay informed about the most suitable options available.

When selecting mill finish steel grating for industrial applications, it’s essential to understand its key features and benefits. Mill finish steel grating is typically used in various sectors due to its excellent load-bearing capacity and durability. According to the American Institute of Steel Construction, the material can withstand heavy traffic loads and extreme environmental conditions, making it ideal for industrial settings.

One of the primary benefits of mill finish steel grating lies in its low maintenance requirements and long lifespan. The absence of coatings or finishes means there's no risk of peeling or flaking, which can occur with painted alternatives. Additionally, mill finish steel demonstrates resistance to corrosion when properly maintained, which is critical in areas prone to moisture and chemicals. A report by the National Association of Manufacturers suggests that the proper treatment of steel can improve its performance, amplifying its suitability for various industrial uses.

Moreover, mill finish steel grating is often more cost-effective, allowing industries to stay within budget while obtaining high-quality materials. Its versatility extends beyond mere flooring solutions, as it can also be utilized for platforms, walkways, and even as a structural component in buildings. In an ever-evolving industrial landscape, understanding the practical applications and advantages of mill finish steel grating is crucial for making an informed choice tailored to specific operational needs.

The mill finish steel grating industry is poised for significant growth, projected to expand alongside trends in related sectors. With increasing demands driven by construction and infrastructure projects, the market is expected to see a surge in usage by 2025. As businesses recognize the versatility and durability of mill finish steel grating, it is essential to analyze the projected growth, which aligns with broader trends in the steel market, estimated to grow at a compound annual growth rate (CAGR) of over 4.2% through 2034.

When selecting mill finish steel grating for your industrial needs, consider the specific applications such as platform floors, drainage covers, and walkways. Understanding your project’s demands will help you choose the right grating size and type that meets safety and performance standards.

Tips: Always review industry data reports for up-to-date information on market trends and forecasts. Additionally, assess the compatibility of mill finish steel grating with other materials in your project to ensure longevity and effectiveness. Keeping abreast of technical specifications will further enhance the decision-making process.

When selecting mill finish steel grating for industrial applications, understanding the different alloy types and their performance implications is crucial. Commonly used alloys include carbon steel, stainless steel, and aluminum, each offering distinct advantages based on environmental conditions and load requirements. According to the American Iron and Steel Institute (AISI), carbon steel grating is cost-effective and caters well to less corrosive environments, but its susceptibility to rust limits its use in harsher applications.

On the other hand, stainless steel, known for its superior corrosion resistance, is favored in industries such as food processing and chemical manufacturing. A study by the National Association of Corrosion Engineers (NACE) indicated that stainless steel grating can last up to three times longer than carbon steel in corrosive environments, significantly reducing long-term maintenance costs. Additionally, aluminum grating provides a lightweight alternative with excellent resistance to both rust and deterioration. Its strength-to-weight ratio makes it ideal for applications where weight constraints are critical. Evaluating these alloy types against specific performance needs ensures optimal selection and longevity of mill finish steel grating in industrial setups.

| Alloy Type | Corrosion Resistance | Weight | Load Capacity | Cost Effectiveness |

|---|---|---|---|---|

| Carbon Steel | Low | Heavy | High | Low |

| Stainless Steel | High | Moderate | Moderate | High |

| Aluminum | Moderate | Lightweight | Low | Moderate |

| Galvanized Steel | Moderate | Heavy | High | Low |

When selecting mill finish steel grating for industrial applications, adherence to safety standards and regulations is paramount. These standards are designed to ensure that the materials used can withstand the rigors of industrial environments while providing safe walkways and platforms. It is essential to consider the American National Standards Institute (ANSI) and Occupational Safety and Health Administration (OSHA) guidelines, which outline requirements for load capacity, slip resistance, and overall durability.

Compliance with these regulations not only protects workers but also helps businesses avoid costly penalties and liability issues. Mill finish steel grating should be assessed for quality marks and certifications that indicate it meets or exceeds these safety standards. Additionally, understanding the specific needs of your application—such as the weight of equipment and foot traffic—will guide you in selecting the appropriate gauge and configuration of steel grating. Prioritizing compliance not only enhances workplace safety but also promotes a culture of responsibility within your organization.

When selecting mill finish steel grating for industrial use, understanding the cost implications is paramount. Initially, lower-grade options might seem more appealing due to their reduced upfront costs; however, the long-term total cost of ownership can overshadow initial savings. A study by the Steel Grating Manufacturers Association reveals that investing in higher-quality grating can yield a return on investment (ROI) of up to 30% over its lifespan through reduced maintenance and replacement costs.

Tip: Always assess the expected lifespan and frequency of use for the grating before making a purchase. For applications that demand high durability, opting for thicker and more resistant materials can significantly decrease long-term expenses associated with wear and tear.

Moreover, don’t overlook the potential for increased productivity linked to grating performance. Data suggests that well-chosen grating can enhance safety and reduce downtime, further solidifying its value. By evaluating the trade-off between initial costs and long-term benefits, businesses can make informed choices that align with their operational goals and financial strategy.

Tip: Consider consulting with a professional to perform a lifecycle cost analysis. This approach ensures that all factors, including maintenance, safety, and potential productivity gains, are weighed against the initial investment for a comprehensive understanding of your choices.