In recent years, the global market for building materials has witnessed a significant transformation, with Plastic Floor Grating emerging as a leading choice for various applications across multiple industries. Manufactured with cutting-edge technology and robust quality standards, Chinese producers have positioned themselves at the forefront of this market, offering products that not only meet but often exceed international expectations. The versatility, durability, and cost-effectiveness of Plastic Floor Grating have made it an essential component in sectors ranging from construction and infrastructure to agriculture and entertainment. This blog will explore the myriad benefits of Plastic Floor Grating, highlighting its contributions to sustainable building practices, safety enhancements, and long-term economic advantages that are driving its growing adoption worldwide. As we delve deeper into this topic, we will uncover why Plastic Floor Grating is not just a trend, but a fundamental shift towards smarter and more efficient material solutions.

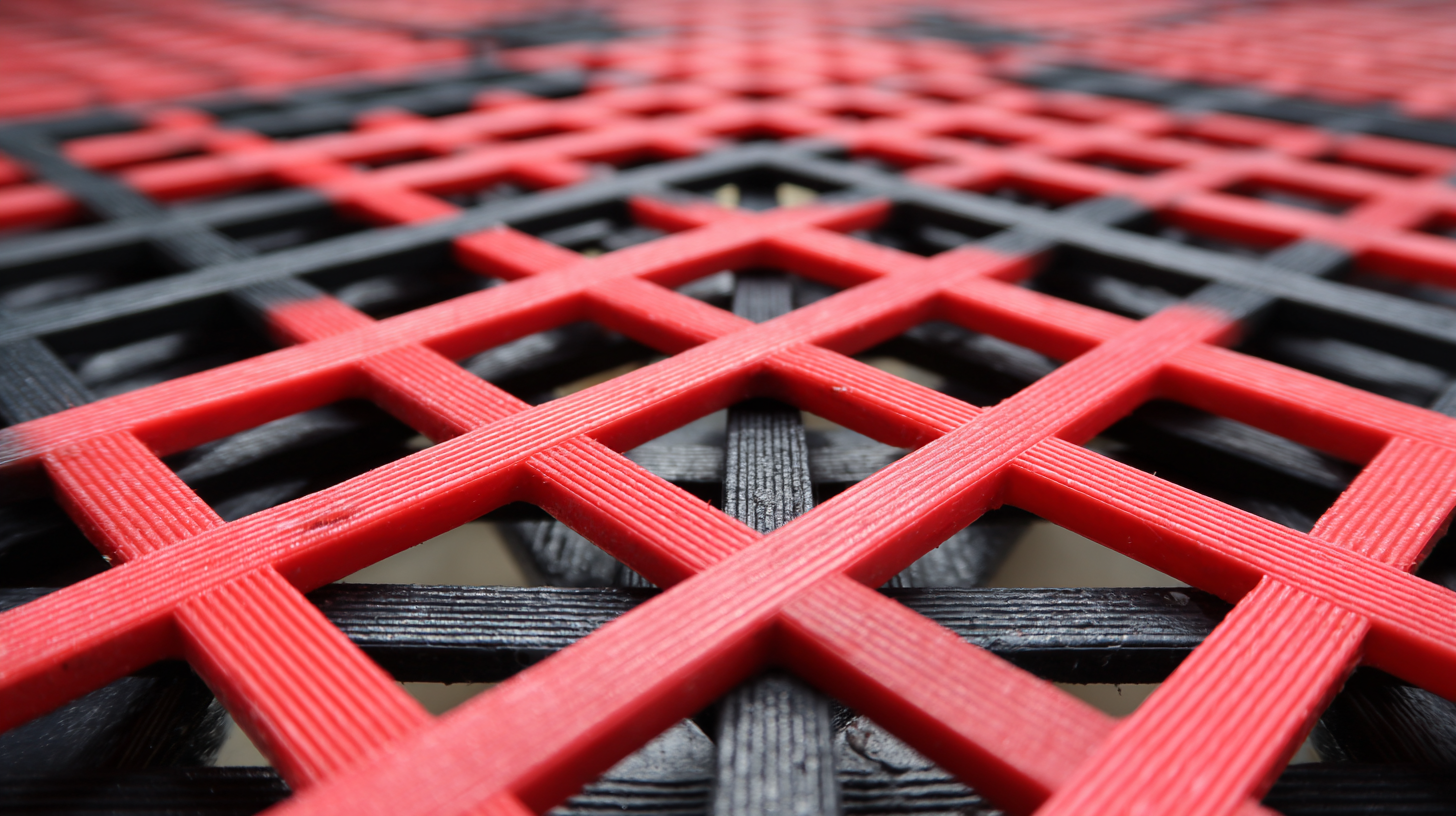

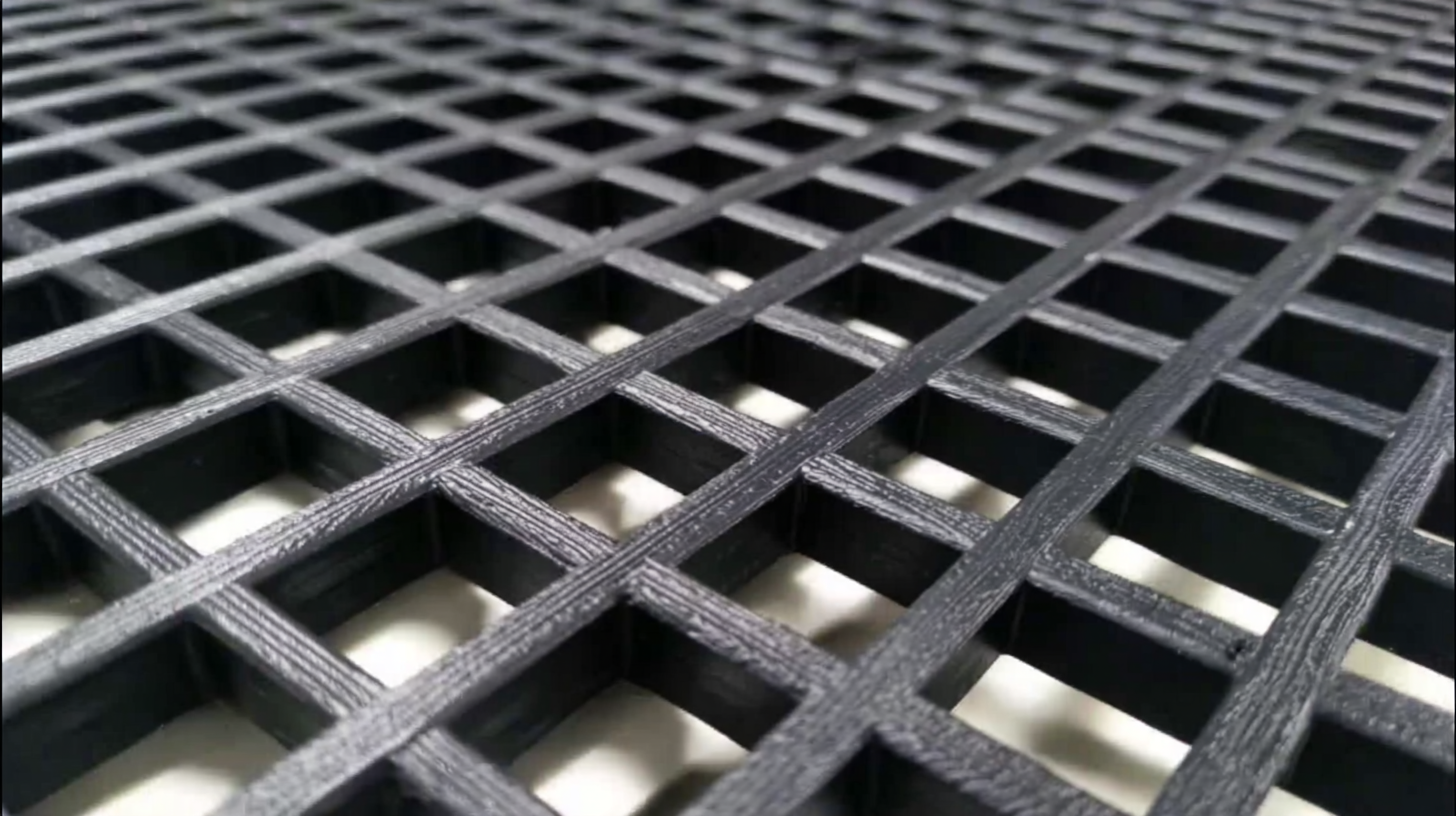

When it comes to industrial applications, choosing the right flooring material is crucial for ensuring safety and efficiency. High-quality plastic floor grating has emerged as a preferred choice for various industries due to its remarkable durability and resilience. Unlike traditional materials, these plastic gratings are resistant to corrosion, chemicals, and UV radiation, making them ideal for harsh environments. This ensures a longer lifespan and lower maintenance costs, providing significant savings for businesses in the long run.

Moreover, the lightweight design of plastic floor grating allows for easier installation and modification, offering flexibility to adapt to changing industrial needs. Its slip-resistant surface enhances workplace safety, reducing the risk of accidents and injuries. With manufacturers in China leading the global market, the high-quality plastic floor grating meets international quality standards, ensuring reliable performance. This blend of durability, safety, and adaptability makes it an excellent investment for any industrial setting, paving the way for enhanced productivity and operational efficiency.

The global demand for lightweight and durable construction materials has surged in recent years, and plastic floor grating, particularly those manufactured in China, are leading this charge. According to a report by MarketsandMarkets, the plastic grating market is projected to reach $523 million by 2025, with a significant portion attributed to advancements in materials technology. This growth is largely due to the advantages that plastic grating offers, including resistance to corrosion, UV degradation, and chemical exposure, making it ideal for various construction environments.

One of the primary benefits of using plastic floor grating in construction projects is its lightweight nature, which facilitates easier handling and installation. This characteristic not only reduces labor costs but also minimizes transportation expenses. Data from the Construction Industry Institute indicates that projects utilizing lightweight materials can see a reduction in overall construction time by up to 25%. Furthermore, the durability of plastic grating, which can withstand heavy loads and harsh conditions, ensures longevity and reduces the need for frequent replacements, making it a cost-effective choice for builders and contractors alike.

When comparing plastic floor grating with traditional materials, it's essential to consider both cost and performance. Plastic floor grating, particularly that manufactured in China, has gained international acclaim for its durability and low maintenance costs. Unlike traditional materials such as wood and metal, plastic grating is resistant to corrosion, making it ideal for environments exposed to moisture and chemicals. This resilience not only extends the product's lifespan but also reduces replacement costs over time.

Tips for choosing the right grating include evaluating the specific requirements of your project, such as load-bearing capacity and environmental conditions. Plastic floor grating is often more cost-effective upfront and can be a smart long-term investment due to its minimal upkeep needs. Additionally, its lightweight nature simplifies installation, saving both time and labor costs.

While traditional materials may offer aesthetic appeal, their long-term performance can fall short in comparison to high-quality plastic options. It’s crucial to assess the total cost of ownership, taking into account factors such as maintenance, replacement frequency, and energy efficiency. Investing in plastic floor grating can lead to significant savings and reliable performance in the long run.

| Material Type | Cost per Square Meter (USD) | Weight (kg) | Durability (Years) | Slip Resistance (Coefficient) |

|---|---|---|---|---|

| Plastic Floor Grating | 25 | 3.5 | 25 | 0.85 |

| Metal Grating | 40 | 8 | 50 | 0.60 |

| Wooden Grating | 35 | 5 | 15 | 0.75 |

| Concrete Grating | 50 | 12 | 30 | 0.50 |

As the global demand for sustainable flooring solutions rises, the importance of environmental impact in product selection becomes increasingly clear.

Plastic floor grating, particularly those manufactured in China, stands at the forefront of this trend. Designed not only for durability and functional efficiency but also for eco-friendliness, these products offer an innovative alternative to traditional flooring materials.

With their lightweight construction, these plastic gratings minimize energy consumption during transportation and installation, contributing to a reduced carbon footprint.

Moreover, the growing livestock flooring market underscores the demand for cost-effective and sustainable options.

Slat floors, interlocking floors, and grating systems made from recycled plastic materials are emerging as viable solutions that combine affordability with durability.

These products are not only designed to withstand harsh conditions commonly found in agricultural settings but also promote sustainability through their recyclable nature.

By opting for these green flooring solutions, consumers not only enhance their operational efficiency but also play a critical role in promoting sustainable practices within the industry.

China has emerged as a powerhouse in the global plastic floor grating market, showcasing remarkable advancements in manufacturing technologies. According to a recent market report by MarketsandMarkets, the plastic grating industry is projected to grow at a CAGR of 6.1% from 2021 to 2026, highlighting a burgeoning demand for high-quality and durable solutions. Chinese manufacturers are at the forefront of this growth, leveraging innovative techniques such as advanced injection molding and fiber-reinforced composites to enhance the performance and longevity of their products.

The technology behind China's leading plastic grating products is characterized by precision engineering and rigorous quality control processes. Many manufacturers have adopted automated production lines, reducing human error and increasing production efficiency. Additionally, the integration of eco-friendly materials is becoming a pivotal factor in product development, aligning with global sustainability initiatives. As a result, Chinese plastic gratings not only meet but often exceed international quality standards, making them a preferred choice in various industries from construction to marine applications.

Tips for selecting the right plastic grating include assessing load-bearing capacity and environmental resistance. Look for certifications and test results from recognized authorities to ensure compliance with industry standards. Furthermore, consider the specific application and location, as different materials may perform better under varied conditions.

This chart illustrates the market share of different regions in the global plastic floor grating market, showcasing China's leading position with innovations in manufacturing.