Accurately calculating the Steel Grating Weight is crucial for a variety of construction and engineering projects, as it directly impacts material costs, load-bearing capacity, and overall structural integrity. According to the

"Global Steel Grating Market Report 2021" published by ResearchAndMarkets.com, the demand for steel grating is projected to grow significantly, driven by its application in industries such as infrastructure, automotive, and energy.

Understanding the weight of steel grating not only aids in budget forecasting but also ensures compliance with safety standards and regulations.

Reports indicate that the weight can vary based on the type of material, design, and manufacturing process, making it essential for professionals to employ accurate calculation methods to achieve the best results in their projects.

This guide will explore the best practices for determining Steel Grating Weight, empowering project managers and engineers to make informed decisions and optimize their designs effectively.

Accurately calculating the Steel Grating Weight is crucial for a variety of construction and engineering projects, as it directly impacts material costs, load-bearing capacity, and overall structural integrity. According to the

"Global Steel Grating Market Report 2021" published by ResearchAndMarkets.com, the demand for steel grating is projected to grow significantly, driven by its application in industries such as infrastructure, automotive, and energy.

Understanding the weight of steel grating not only aids in budget forecasting but also ensures compliance with safety standards and regulations.

Reports indicate that the weight can vary based on the type of material, design, and manufacturing process, making it essential for professionals to employ accurate calculation methods to achieve the best results in their projects.

This guide will explore the best practices for determining Steel Grating Weight, empowering project managers and engineers to make informed decisions and optimize their designs effectively.

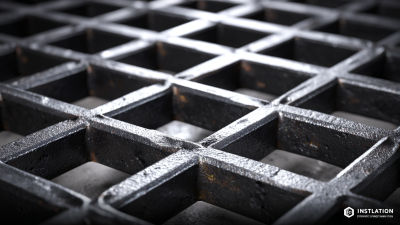

When calculating the weight of steel grating, understanding the basic materials and specifications is crucial. Steel grating is primarily made from carbon steel or stainless steel, each offering different properties suited for various applications. Carbon steel is typically more economical and provides good strength, while stainless steel is favored for its corrosion resistance, making it ideal for outdoor or chemically exposed environments. Familiarizing yourself with the type of steel you choose will aid in accurate weight calculations.

Tips: Always check the specifications of the grating being used, as different types (like welded or press-locked grating) have varying thicknesses and widths, directly affecting the weight. Additionally, consider measuring the size of the grating panels accurately, as precise dimensions can significantly influence your total weight estimation.

Another essential aspect is to understand the load capacity and spacing of the grating bars. This not only impacts performance but also weight. For example, closely spaced bars generally increase the weight while enhancing strength. When planning your projects, ensure that all specifications align with the intended application to ensure safety and functionality while keeping your calculations precise.

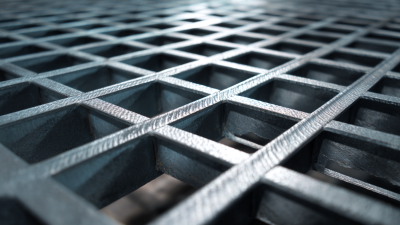

When calculating the weight of steel grating for your projects, determining the dimensions and thickness is crucial. The first step is to measure the length and width of the grating panels. These dimensions directly influence the surface area, which is a key factor in weight calculation. Ensure that measurements are precise, as even minor discrepancies can lead to significant variations in your final weight assessment.

When calculating the weight of steel grating for your projects, determining the dimensions and thickness is crucial. The first step is to measure the length and width of the grating panels. These dimensions directly influence the surface area, which is a key factor in weight calculation. Ensure that measurements are precise, as even minor discrepancies can lead to significant variations in your final weight assessment.

In addition to dimensions, the thickness of the steel grating plays a vital role in determining its weight. Steel grating is available in various thicknesses, typically ranging from 1/4 inch to 1 inch. The thicker the grating, the heavier it will be. To obtain an accurate weight, refer to the manufacturer's specifications, which usually provide weight per square foot or square meter based on thickness. By carefully measuring dimensions and selecting the appropriate thickness, you can achieve an accurate calculation of the total weight for your steel grating needs.

When calculating the weight of steel grating for your projects, utilizing weight formulas and conversion factors is essential to achieve accuracy. Steel grating is commonly used in various applications due to its strength and versatility, but its weight can vary significantly based on dimensions, bar spacing, and material thickness. To begin with, you need to know the density of the steel you are working with, which is usually around 490 pounds per cubic foot (pcf). By applying this density in conjunction with the grating's dimensions, you can derive a precise weight estimate.

To calculate the weight, use the formula: Weight = Volume x Density. First, determine the volume by measuring the grating's length, width, and thickness. Multiply these three dimensions together to find the volume in cubic feet. Once you have the volume, you can multiply it by the density of the steel to get the total weight. Additionally, when dealing with international projects, it's important to apply appropriate conversion factors to switch between metric and imperial units if needed. This ensures that your calculations remain consistent regardless of the unit system in use.

When calculating the weight of steel grating for your projects, it’s essential to understand the different types available and their respective dimensions. For instance, a standard welded steel grating often measures 1 inch in thickness. To determine its weight, you can use the formula: weight = volume × density. The density of steel generally ranges from 490 to 500 pounds per cubic foot. This means a 4-foot by 8-foot section of the grating would weigh approximately 100 pounds if it is 1 inch thick, allowing for precise planning in material selection and cost estimation.

Taking another example, consider a bar grating, which typically has a different structure and thickness options. If the grating has a thickness of 1.5 inches and measures 3 feet by 10 feet, its volume calculation would yield a different weight. Using the same density values, the total weight can be calculated to guide transportation and installation processes effectively. By conducting these calculations accurately for each type of steel grating, project managers can ensure they allocate the right resources and maintain structural integrity in their designs.

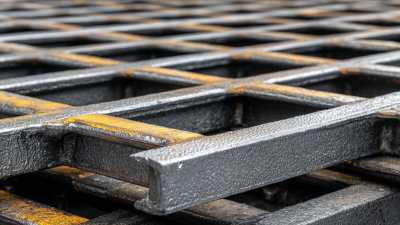

When calculating the weight of steel grating for your projects, there are several common mistakes that can lead to inaccurate results. One of the most frequent errors is neglecting to account for the specific type of grating being used. Different configurations, such as welded or pressed grating, have varying material densities and structural characteristics. Failing to reference the correct specifications can result in significant deviations from the actual weight.

Another mistake often made involves the miscalculation of dimensions. It's essential to measure the length, width, and thickness accurately, as even minor discrepancies can drastically affect the weight calculation. Additionally, overlooking the impact of accessories, such as framing and support systems, can accumulate additional weight that needs to be factored into the final estimate. By being diligent in these areas, you can ensure a more precise calculation of steel grating weight, ultimately improving the reliability of your project planning.

| Grating Type | Dimensions (inches) | Weight per Square Foot (lbs) | Common Uses |

|---|---|---|---|

| Heavy Duty | 24 x 48 | 10.5 | Construction, Industrial Flooring |

| Standard Duty | 30 x 60 | 7.5 | Sidewalks, Walkways |

| Light Duty | 36 x 36 | 4.5 | Light Traffic Areas |

| Steel Bar Grating | 24 x 24 | 6.5 | Drainage Covers, Ventilation |

| Infloor Grating | 48 x 48 | 8.0 | Mechanically Ventilated Spaces |